Bearings

Rolling bearings

Rolling bearings support and guide rotating or oscillating machine elements – such as shafts, axles or wheels – and transfer loads between machine components. They provide high precision and low friction and therefore enable high rotational speeds while reducing noise, heat, energy consumption and wear. The two most common types of rolling bearings are ball bearings and roller bearings.

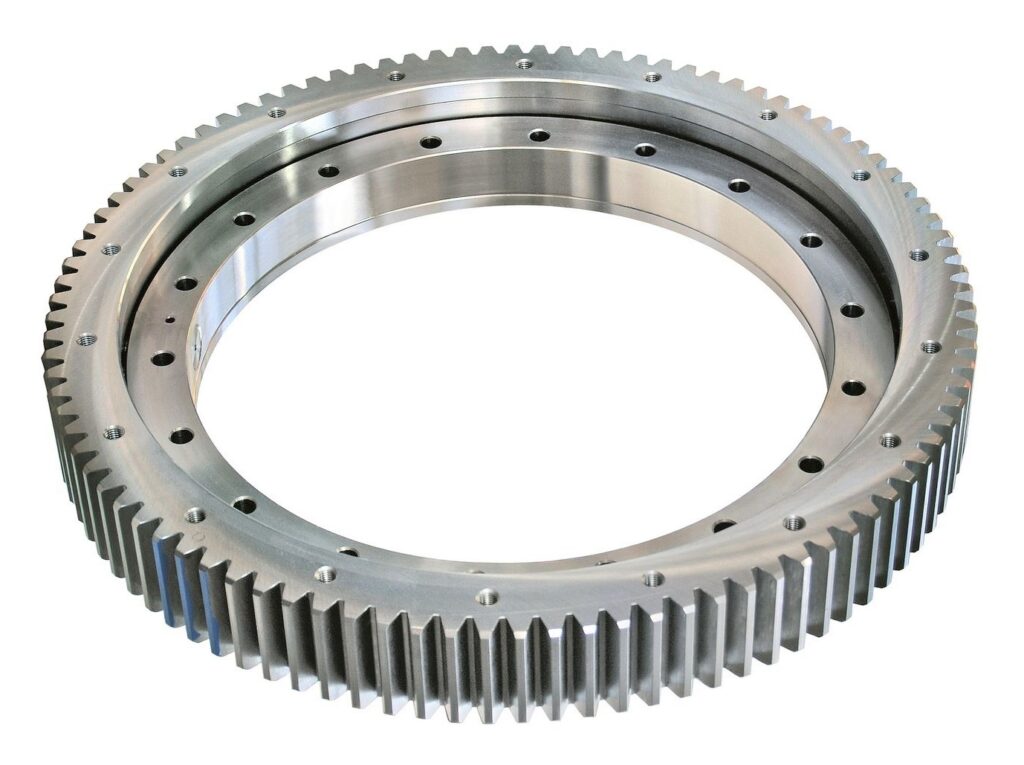

Slewing bearings

Slewing bearings consist of an inner and outer ring, where one of the two rings generally incorporates a gear.

Thin section bearings

Thin section bearings are designed to save weight, use less space, reduce friction, increase design flexibility, and provide high running accuracy.

Magnetic bearings

Magnetic bearings and systems are ideal for applications demanding high speeds and low vibration.

Plain bearings

Plain bearings with spherical sliding surfaces can accommodate alignment, tilting and/or slewing movements.

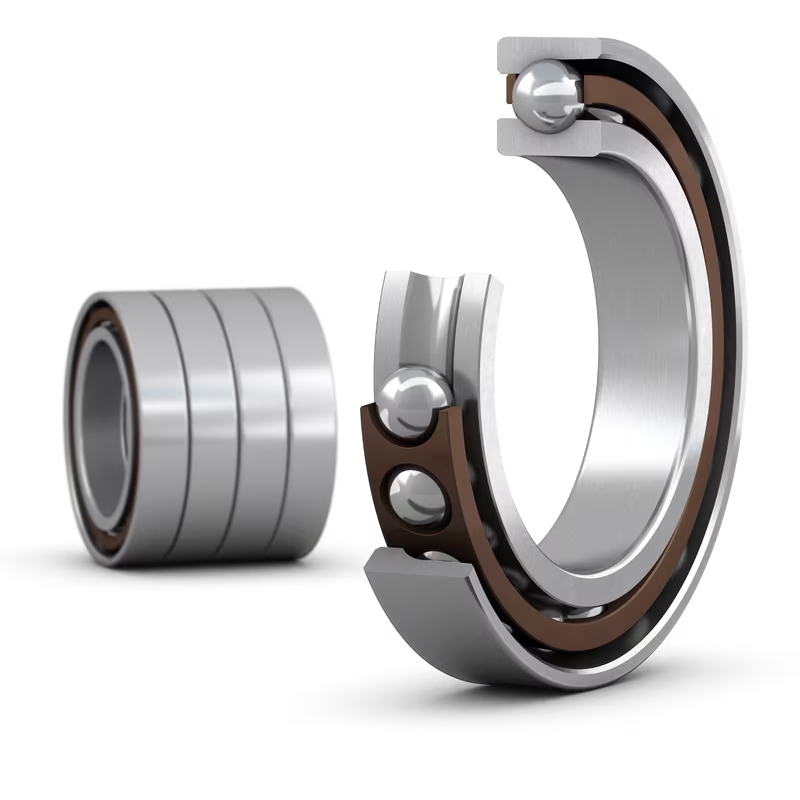

Super-precision bearings

Super-precision bearings are ideal for machine tools or precision applications where high running accuracy, high-speed performance and high system rigidity are needed.

Mounted bearings and housings

The mounted bearings and housings with rolling bearings support a rotating shaft by compensating for misalignment or transmitting loads to surrounding machine structure.